Meet the Next Generation of Pump & Sprayer Capping

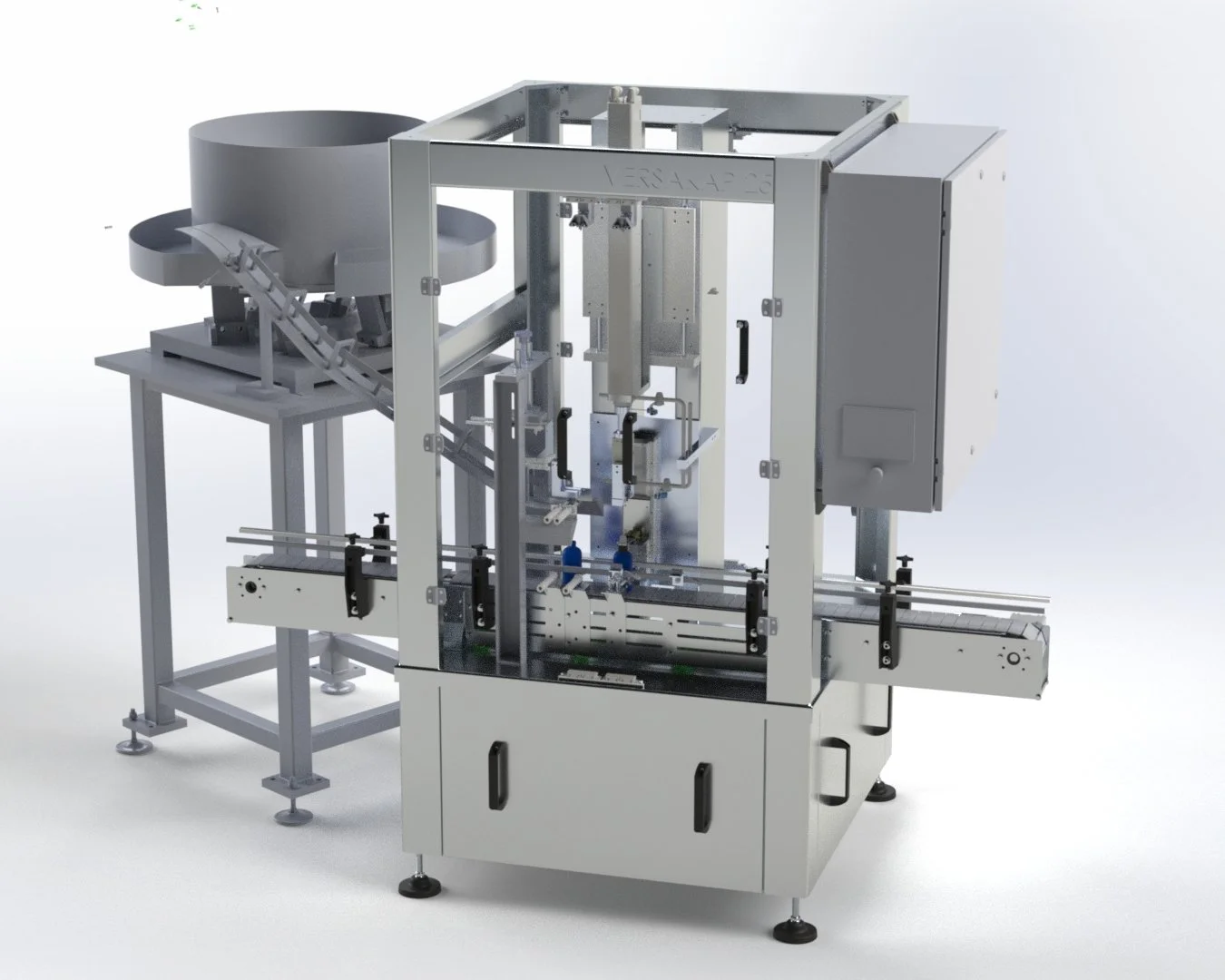

Introducing the SK VersaKap 25

The SK VersaKap 25 is a brand-new automatic capping machine for pumps and spray bottles, engineered for today’s production demands. It’s designed to reduce labor costs, lock in consistent torque and deliver fast ROI by bridging the gap between hand-capping and oversized rotary machines.

Compact yet powerful, the VersaKap 25 gives manufacturers a smarter, more affordable way to automate pump and sprayer capping at speeds of up to 25 bottles per minute.

How It Works

Built with servo-driven design, the SK VersaKap 25 allows precise adjustments to torque and motion profiles through a single HMI interface. Integrated bottle separation and indexing ensures stable, accurate placement. An onboard QC system measures torque in real time, automatically rejecting improperly capped bottles — maintaining quality without additional operators.

Why It Matters

Labor savings: Eliminate the inefficiency of hand-capping

Consistent performance: Precise torque and placement every time

Compact footprint: A better fit for modern production lines

ROI in a year: Servo-driven design delivers fast payback and long-term reliability

Quality assurance built in: Inline QC prevents errors before they leave the line

Technical Highlights

Throughput: Up to 25 bottles per minute (ideal for mid-range production)

Servo-driven design: Fine-tuned torque and motion profiles via HMI interface

Integrated bottle separation & indexing: Stable, accurate placement every time

Real-time QC system: Measures applied torque, rejects non-conforming caps automatically

Compact footprint: Fits easily into existing lines

Washdown-ready construction: Built tough for food, personal care, household & ag applications

American-made: Backed by SureKap and Excelis Automation service and support

Schedule a Consult

Get in the queue for 2026 production by filling out the free consult form below.